Ion Techniques is serving various industries listed below for the past 40 years providing Fool Proof Water Treatment Solution and achieving Zero Failure plants across India.

ION Techniques have always been the leading players in offering ETP or Effluent Treatment Plant solutions. ION Techniques have dealt with major turnkey projects in all types of industries and sectors. The business world and the domestic world have understood the importance of ETP’s and the benefits it has to offer to our environment and to generations to come.

ION Techniques follows the guidelines laid by Pollution Control board, takes on turnkey projects pan India and even offers maintenance of Effluent treatment plants.

We serve the following industries:

Textile, Food Processing, Petro Chemical, Fertilizer, Heavy Metal, Sugar, Pulp, Paper, Automobile, FMCG, MiningJet Aeration

The jet aerators are designed with jet aeration nozzles. This configuration is most applicable for square or rectangular tanks and sequence batch reactors where directional flow patterns are not desired.

Dual Media Filter (DMF)

Sand Filter is based on Flui-FiltTM Technology. Conventional filtration is ‘surface filtration’ i.e. filtration occurs just on the top of the surface of sand and the rest of the media depth is only to provide the basic foundation for the top layer. In Flui-FiltTM, the entire media does filtration. The concept is to provide surface filtration through the entire depth of media.

Micro Filtration / Ultra Filtration

Salient Features

- Anti-Hammering design

- Zero leakage plant for years

- Fully Automatic

- Robust anti-vibrate heavy load bearing MS structure skid boxed with 5.7mm thickness channels with anti-corrosive coating

- All piping in the skid are SCH10 SS316 L make

Engineering

- The MF plant is engineered by highly qualified engineering team from inland and international.

Manufacturing

- The MF plant is manufactured by talented & innovative skilled team of qualified engineers

- State of the art technology is incorporated in the manufacturing process

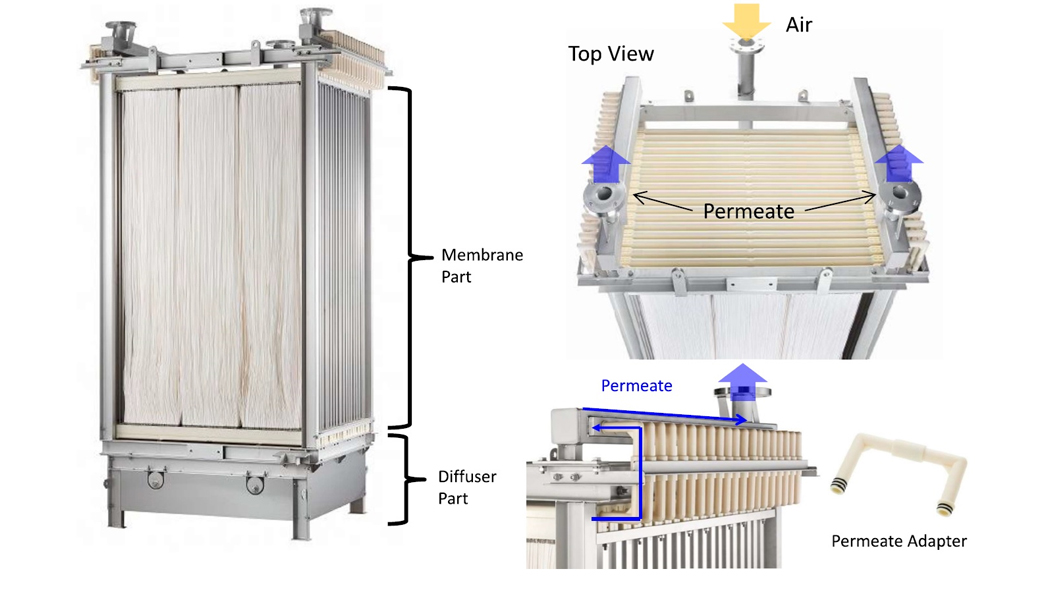

Membrane Bio Reactors

We offer MBR application products for wastewater treatment, drinking and processing water treatment.

- Life expectancy 8 - 10 years

- Easy Storage

- No Need Backwash

- No Need Drain Membrane Tank

- Available integrated MBR System

Reverse Osmosis

Salient Features

- Corrosion resistant FRP RO housings with side port.

- Online TDS transmitter, ORP transmitter, Pressure transmitter provided for highest level of performance.

- Considered 10% fouling of membranes in the design.

- Two stage RO system providing for high recovery .

- SS 304 SKID

- Imported high pressure multistage vertical centrifugal pumps.

- Imported high quality reverse osmosis membranes.

- CIP chemical cleaning system to increase the life of membranes.

- High quality Bag and Micron filter .

- All high pressure pipelines and fittings are in Stainless Steel 304.

- The equipment is factory tested prior to shipment.

Nano Filtration

This Nano Filtration plant is designed to treat the waste water which cannot be treated with normal NF plant. High turbulence is created with in the Nano Filtration system to prevent deposition of scaling, fouling and deposits. Special software programs for automation, eloquent instrumentation, engineering and unique membranes are provided. This Nano Filtration system is an innovation by Ion Techniques. It is a state of the art new technology.

Mechanical Vapor Recompressor

Mechanical Vapor Recompression (MVR) is a proven energy-saving evaporative concentration technology, which reduces evaporation energy use by 90% or more. We do modular, compact and robust MVRs.

Evaporator

ION Techniques design the industrial evaporator plants to meet stringent guidelines and regulations laid by the pollution control board. We offer bespoke services as we are masters in understanding the industry requirements, reduced costs and energy usage during the evaporation process.

Our evaporators are durable and efficient.Agitated Thin Film Dryer

ATFD is an ideal apparatus for continuous processing of concentrated material into dry solids. The device consists of a cylindrical and vertical body covered with a heating jacket. Equipped inside is a row of pendulum blades that spread the wet feed product in the form of a thin film.

Sludge Compactor

Ion Techniques always focus on innovative independent technologies within us. Along with the cooperation from various research companies, we have successfully developed the new generation sludge dewatering technology called the Sludge Compactor, which is much more advanced in very aspects than belt presses, centrifuges, plate type filter presses, etc. It features clog-free, wide range of applications, low energy consumption, simple operation & maintenance (Automated).

Our Workmanship